Unlocking the Power of Cross-Docking: Key Insights for Supply Chain Management Success

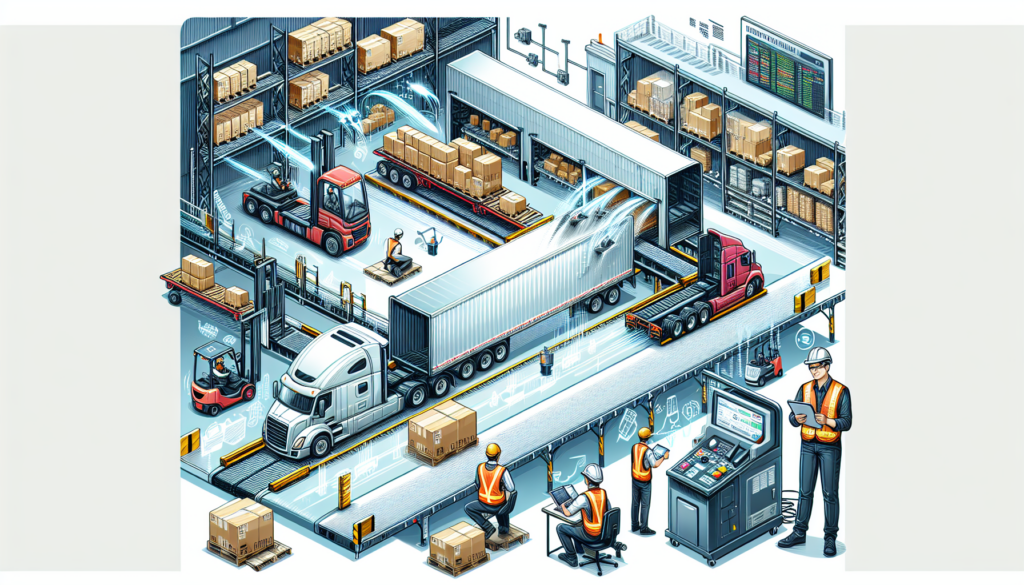

[ad_1] Unlocking the Power of Cross-Docking: Key Insights for Supply Chain Management Success In today’s fast-paced world of e-commerce and global trade, supply chain management is more critical than ever. Companies are constantly seeking ways to streamline their operations, reduce costs, and improve efficiency. One strategy that has gained popularity in recent years is cross-docking. What is cross-docking, and how can it benefit your supply chain? In this article, we will explore the ins and outs of cross-docking and provide you with key insights to help you unlock its power for your business. What is Cross-Docking? Cross-docking is a logistics strategy where incoming goods are directly unloaded from inbound vehicles and loaded onto outbound vehicles with minimal or no storage in between. This process eliminates the need for traditional warehousing and storage, allowing for faster transit times and reduced handling costs. Cross-docking can be especially beneficial for companies with high-volume, fast-moving products, such as retailers and e-commerce businesses. By bypassing the traditional warehousing step, companies can reduce inventory holding costs, minimize the risk of stockouts, and improve order fulfillment speed. Key Benefits of Cross-Docking 1. Improved Efficiency: Cross-docking helps streamline the supply chain by reducing the time and costs associated with storing and handling inventory. By eliminating the need for warehousing, companies can speed up order fulfillment and reduce lead times. 2. Cost Savings: By reducing inventory holding costs and minimizing storage space requirements, cross-docking can lead to significant cost savings for businesses. Companies can also benefit from lower transportation costs due to faster transit times and reduced handling. 3. Enhanced Visibility: Cross-docking provides companies with greater visibility into their supply chain operations. By eliminating the need for warehousing, companies can track their products more effectively and make informed decisions based on real-time data. 4. Increased Flexibility: Cross-docking allows companies to respond quickly to changing market demands and customer preferences. By bypassing traditional warehousing, companies can adjust their inventory levels and distribution strategies in real-time. 5. Eco-Friendly: Cross-docking can also have environmental benefits by reducing the carbon footprint of supply chain operations. By minimizing storage and handling, companies can lower their energy consumption and greenhouse gas emissions. Implementing Cross-Docking Successfully To unlock the full potential of cross-docking for your business, it is essential to carefully plan and execute the process. Here are some key tips for implementing cross-docking successfully: 1. Strategic Planning: Before implementing cross-docking, assess your supply chain needs and identify areas where cross-docking can add value. Consider factors such as product volume, transit times, and customer demand to determine the best approach for your business. 2. Collaboration: Effective communication and collaboration between stakeholders, including suppliers, carriers, and customers, are crucial for successful cross-docking. Ensure that everyone is aligned on the process and expectations to avoid any disruptions in the supply chain. 3. Technology Integration: Utilize technology solutions such as warehouse management systems (WMS) and transportation management systems (TMS) to optimize cross-docking operations. These tools can help track inventory, manage shipments, and streamline communication between stakeholders. 4. Continuous Improvement: Regularly monitor and evaluate your cross-docking operations to identify areas for improvement. Analyze key performance indicators (KPIs) such as order fulfillment speed, transportation costs, and inventory turnover to optimize your supply chain processes. Frequently Asked Questions Q: What types of products are suitable for cross-docking? A: Cross-docking is best suited for high-volume, fast-moving products with consistent demand. Industries such as retail, e-commerce, and manufacturing can benefit the most from cross-docking. Q: How can cross-docking help reduce transportation costs? A: By minimizing storage and handling, cross-docking can lead to faster transit times and lower transportation costs. Companies can also benefit from reduced fuel consumption and fewer empty miles. Q: What are the potential challenges of implementing cross-docking? A: Some challenges of cross-docking include coordination between stakeholders, technology integration, and inventory management. However, with proper planning and execution, these challenges can be overcome to unlock the benefits of cross-docking. In conclusion, cross-docking is a powerful strategy that can help companies streamline their supply chain operations, reduce costs, and improve efficiency. By implementing cross-docking successfully and leveraging its key benefits, businesses can stay competitive in today’s dynamic marketplace. Unlock the power of cross-docking for your business today and experience the transformative impact on your supply chain. For more information on how Fulfillment Hub USA can help optimize your supply chain with cross-docking solutions, visit https://fulfillmenthubusa.com. [ad_2]

Unlocking the Power of Cross-Docking: Key Insights for Supply Chain Management Success Read More »