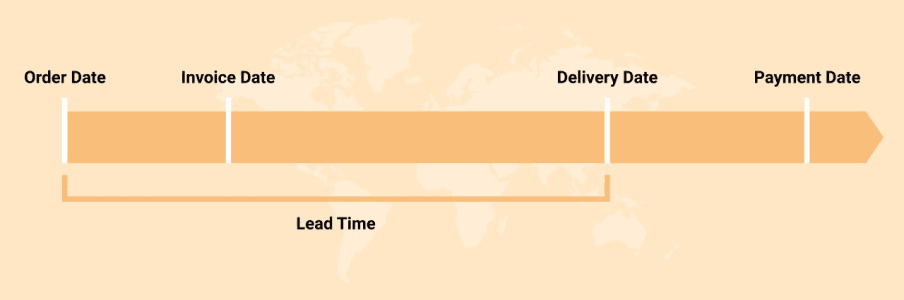

Do you know the secret to retaining your customers? There are many of them. However, one aspect of your order fulfillment process impacts it the most, which is Lead Time. It is the amount of time between initiation and completion of any process. For businesses, lead time is the amount of time between a customer placing an order and the services/products delivered to them.

Lower your lead time, and expand your customer base with Fulfillment Hub USA!

Lead time has many types, and it impacts the way a business operates. It also affects the quality of services. In this article, we will dive into what it is, its types, why it should be less, and how to optimize it. Let’s begin, shall we?

Content Topic

Everything You Need to Know About Lead Time

When a customer places an order, they want it to be delivered quickly. One study found that 14% of consumers abandon the seller if they receive a late delivery just one time. Hence, if your e-commerce fulfillment process takes too long, you’ll lose sales. In order to retain your customers, make sure to reduce your lead time.

What is Lead Time?

Lead time is the amount of time that goes by from the start to the finish of any given process. For eCommerce businesses, it affects every stage of the supply chain. Moreover, it determines the quality of your services. If it gets out of control, it can cause huge issues in inventory management and the order fulfillment process. Hence, it is essential to optimize lead time.

Types of Lead Time

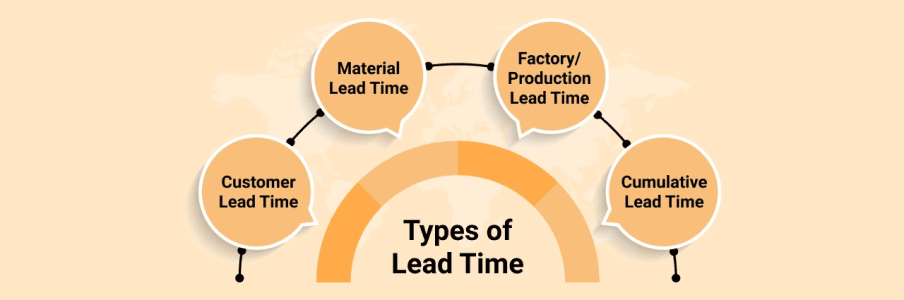

There are various types depending mainly on the operations of a business. For example, for an eCommerce business and fulfillment center, there are four important types:

Customer Lead Time

It is the amount of time taken between order confirmation and order fulfillment.

Material Lead Time

This is calculated after the customer places an order. It is the amount of time it takes to place an order with a supplier (in case you are out of stock) and receive it.

Factory/Production Lead Time

This time is calculated when you have the product in stock with you. It is the amount of time it takes to pick, pack, and ship a product if all the materials are available.

Cumulative Lead Time

This is the summation of material lead time and factory lead time. It is the total amount of time it would take from confirmed order to delivery of the product.

Customer lead time is the crucial marker in determining the satisfaction of your eCommerce business, while cumulative lead time affects inventory planning and cash flow.

Lead Time VS Cycle Time VS Takt Time

Lead time is somewhere related to cycle time and takt time, but it also differs from them in certain aspects.

-Takt Time: It is the rate at which you need to complete the production process in order to meet customer demand.

-Cycle Time: It is the amount of time it takes to manufacture a product from start to end.

Takt time is based on customer demand, whereas cycle time depends on the work process. Therefore, always make sure that your cycle time fits your ideal takt time. You can make some adjustments to achieve this. Additionally, it provides you with a shorter lead time, which in turn helps fulfill customer demands.

Importance of Shorter Lead Time in Fulfillment

This determines many aspects of the supply chain. Hence, understanding and controlling lead time is paramount. When it is optimized, it becomes easy to manage inventory and fulfill orders on time.

Customer Satisfaction and Retention

When delivery time is less, your customers receive their orders on time. Hence, customers are more likely to return and rate your services positively.

Enhanced Supply Chain Operations

Delivery time affects supply chain operations. Delay in order-fulfillment is less when lead time is less. Moreover, higher lead time increases the inventory count. Hence, with the help of it, you can optimize your supply chain operations.

Factors Affecting Lead Time

There are several factors:

Stockouts

Stockouts can affect any element of your supply chain. If you don’t have products or can’t get them on time, you can’t fulfill orders on time. Stockout can be a result of miscalculating your lead time. Focus on avoiding this situation, if you run an eCommerce business.

Shipping Delays

From human errors to natural disasters, there are many factors that are uncontrollable and can cause a delay in shipping. Unfortunately, it’s impossible to eliminate shipping delays. However, you can always opt for a 3PL like Fulfillment Hub USA that is proactive in finding workarounds for shipping issues.

Inefficient Inventory Management

An inventory management system helps you manage your inventory with ease. When you have an efficient inventory management system, you can easily overcome reorder delays and save your inventory from misplacement, loss, or damage. If you have an inefficient system, it can lead to a higher lead time. Hence, try to implement automated inventory management software to reduce delays and fasten the order-fulfillment process.

Lead Time Variability

The amount of time it takes to get your products delivered from different suppliers is unpredictable. Therefore, a delay from any supplier can lead to a higher lead time for you. To avoid this, consolidate suppliers so that you’ll get all that you need for order fulfillment at the same time.

Lead Time Reduction

Higher lead time impacts the lifespan of a business. It determines customer satisfaction, quality of the services, and sales. Hence, it is important to reduce the delayed shipping to scale your eCommerce business. Though uncontrollable factors affect your total lead time, you can take several steps to minimize it.

Use Contract with Suppliers

Start by creating a contract with suppliers that include definite timeframes. Some suppliers promise timely delivery but fail to deliver. This results in a higher lead time. The best way to avoid this is to have a legal agreement that includes the following elements:

– Delivery time for specific orders

– Advance notice of price changes or stock shortages

– Liability for damaged or incorrect goods

– Penalty for delayed shipments

– Agreed-upon delivery time for all orders

Reorder More Often

If placing large order demands a higher turnaround time, it’s worth ordering in smaller quantities. Adjust your reorder points and try a different warehousing approach to lower your lead time.

Share Inventory Forecasting with Your Suppliers

If you are expecting a huge sale in the future, let your suppliers know about it. Then, they can prepare the goods in advance for you and deliver them on time. This helps you reduce delays and serve your customers with timely delivery.

Provide Incentives to Suppliers

As discussed above, you should apply a penalty to suppliers for the late delivery. So, it would be best to offer incentives to suppliers who deliver on time or in advance. When you appreciate their services, it gives them a boost to deliver on time in the future.

Declutter Non-Value-Adding Tasks

Among various activities that you perform in the order fulfillment process, make a list of all the activities and determine processes that do not add value or prolong lead time. Then, eliminate all those activities or only keep those that impact the process remarkably.

Try Kitting

When you kit products that are ordered frequently together, you limit the time it takes to pick, pack, and ship products. Hence, with kitting, you can easily reduce your delivery time.

Explore Shipping Methods

Check out different shipping methods if the one that you are using is causing delays in shipment. It can lead to a higher cost than the preferred shipping method, but it’s worth checking out if it reduces your lead time and improves your services.

Use Inventory Management Software

When you manually manage everything, there’s a high risk of human errors. Hence, it is effective to use a better inventory management system that automatically tracks everything and gets you insights into inventory and forecast demands.

Essential Formulas

Here are some essential formulas that help you calculate important metrics:

Lead Time (LT):

For manufacturers,

Total LT = Manufacturing Time + Procurement Time + Shipping Time

For retailers,

Total LT = Procurement Time + Shipping Time

Procurement time can include the amount of time it takes to pick and pack goods.

Cycle Time:

Cycle Time = Net Production Time / No. Of Units Produced

Takt Time:

Takt Time = Net Production Time/Units Required (Customer Demand)

Lead Time in a Nutshell

It is a crucial metric for an eCommerce business. It determines operational flow, cost, productivity, customer satisfaction, and ultimately, sales. Therefore, if you want to optimize your order-fulfillment process, you should focus on reducing your lead time.

Optimize Lead Time with Fulfillment Hub USA

Fulfillment Hub USA is your tech-driven 3PL partner. We offer affordable eCommerce fulfillment with tech-integrated inventory management solutions. Our 5-in-1 cloud-based software helps you track your inventory in real-time, provides you insights, helps you forecast demands, and much more.

We equip your business with the latest technologies to help you reduce your lead time. Moreover, you get access to the best shipping partners worldwide and their timely delivery services. Contact our experts today to lower your shipping time and enhance your customer’s experience with us.

FAQs

What is lead time?

Lead time is the amount of time it takes for a process to complete from beginning to end. For businesses, it is the amount of time from the moment a customer places an order to when they receive the product.

What is lead time formula?

Lead time (LT) is calculated as the total time it takes to pick, pack, ship, and deliver products.

For manufacturers,

For manufacturers,

Total LT = Manufacturing Time + Procurement Time + Shipping Time

For retailers,

Total LT = Procurement Time + Shipping Time

Procurement time can include the amount of time it takes to pick and pack goods.

What is lead time gap?

Lead time gap is the difference between logistics lead time and customer order cycle time.

Logistics Lead Time = total time to complete the picking, packing, and shipping. If you manufacture the product, then add manufacturing time as well.

Customer Order Cycle Time = the amount of time the customer is prepared to wait for the product to arrive from the moment the order is placed.

What are the types of lead time?

There are basically four types of lead time: customer lead time, material lead time, factory/production lead time, and cumulative lead time.