Content Topic

In the modern-day interconnected world, customers are almighty. They search, select, and swipe their way to purchase the products they like. In such a just-in-time, instant gratification era, people hate to see out-of-stock notifications. Nevertheless, sometimes due to issues in the supply chain, an item goes out of stock.

Now you must be thinking, what to do if any products are out of stock? It’s simple – Backorder. Sellers use backorder as a way to deal with the situation of being out of stock. However, it is not ideal. Consumers do not like to wait to get the products they like.

If you are an e-commerce retailer and have high backorder rates, it means there are issues with your inventory management.

Save your business from Backorder!

Here is an article with all you need to know about backorder meaning, causes, and tips to deal with it.

All About Backorder in Inventory Management

Purchasing goods online has become a common practice at the present time. The number of digital buyers is growing every day. According to a report published by Statista, there were 1.66 billion digital buyers across the globe and this number is expected to rise rapidly. The figure reflects the need of managing inventory adequately to avoid situations like ‘backorder’ or ‘out of stock.’

If you are struggling to restock products onto your warehouse shelves or manage your inventory restocking, then you have two options. Either you can accept backorders or mark the products as out of stock. We will talk you through about backorder in this article.

What is Backorder?

When an item is in backorder, it means currently it is out of stock, but is expected to be delivered as soon as it is back in inventory by a specific date. Businesses sell backordered products and also give the assurance to deliver the products to the buyers.

Backordering any product means the customer can purchase the item now and get it delivered on a future date when it is back in stock. In the case of backordering, an item cannot be packed and shipped at the time of ordering due to a lack of physical products in the inventory. It makes them different from just in-time inventory and discounted inventory.

Difference between Backorder and Out of Stock

Out of stock implies that a particular product is currently unavailable in the inventory and there is no fixed date for resupply. On the other hand, backordered means that the product is not present in the stock currently but there is a fixed date for the product to arrive.

To succinctly describe, it is the difference between “This item is out of stock” and “This item cannot be shipped until a particular date.”

In the case of backordering, it might take some time but you will definitely get the product. On the other hand, in the case of ‘out of stock’, there are probabilities that the product might be permanently unavailable. There are also the cases when seller has no idea when the product will be back.

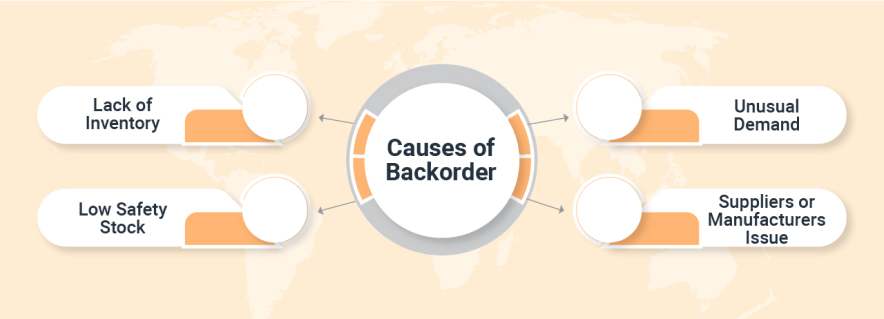

Causes of Backorders

There are various causes of backorder. Some of them are out of control, while others are preventable. Below mentioned are some of the common causes of backorders.

Lack of Inventory Control

If a business firm does not have adequate stock levels or it is unable to keep proper track of the inventory movement, then there are higher chances of backorders. In the modern-day world, the trends are changing rapidly and the number of SKUs for each online store is increasing. Under such situations, it is essential to use the right inventory management system to ensure a smooth flow of operations.

In the contemporary competitive era, there is higher importance of an accurate inventory management system for a business. A good or tech advanced inventory management software can help you monitor your inventory properly. It can keep you from running short on stock for your products.

Low Safety Stock

Safety stock refers to the extra number of items you keep in inventory to handle supply failure or emergency cases that can lead to inventory unavailability. If there is a lack of a products’ safety stock, you may face situations of out-of-stock or backorder.

Unusual Demand

When there is an irregular high demand for a product on an online store; there are higher chances of backorders. In many cases, it is quite difficult to predict the unprecedented surge in demand despite decent sales forecasting. There could be various reasons for unusually high demands like seasonality, influencer marketing, or affiliate marketing. Moreover, the introduction of a new sales channel can also boost the product demand.

Supplier or Manufacturer Issues

If your manufacturer runs out of the raw goods needed to manufacture the products, then you need to shut down the business for a long period of time. It can also keep you from hitting your production goals for a long time period. In such a situation, your online store may face the issue of backorder.

Tips to Minimise Backorders

Though backorders are unplanned and inevitable in some cases, there are some measures you can use to reduce the chances of them occurring. Here are some tips to help you minimize backorders.

Set Reorder Points

A reorder point refers to the minimum quantity of products that a business should keep before the need to reorder more units of a product from the manufacturer. A simple formula to calculate reorder is by adding the available safety stock and lead time demand.

At Fulfillment Hub USA, we have 5-in-1 cloud-based software that allows you to calculate reorder points for each product. Moreover, it also alerts you when there is a need to restock inventory.

It is always a good idea to increase the reorder quantity during upcoming promotions, product launches, and flash sales. Moreover, you should also pay attention to your historical data as it can help you get an idea about the months when sales are high and you would need additional inventory.

Monitor the Inventory Levels of Popular Products

Popular products or the ones high in demand may sell out quickly as compared to others. Therefore, it would be better to keep an eye on the stock level of these products. In the e-commerce world, nothing can go perfectly according to the plan, so ensure to monitor the inventory regularly to manage the inventory restocking effectively.

Keep Safety Stock

In order to run an e-commerce business successfully, it is better to have a technically advanced inventory management system. It can help you to keep a track of the products available in stock in real-time. Setting a safety stock point is one of the best ways to handle supplier problems and unusual demands. It is always a good idea to keep extra stocks in hand, have real-time inventory tracking, and replenish inventory proactively to prevent backorders.

Get Products from Multiple Suppliers

Having multiple suppliers for your items has its benefits. Many times, backorders are caused when a supplier or manufacturer is unable to supply enough products in time. Working with multiple suppliers can help you avoid this problem.

Order More Products

The right quantity of safety stock is the best solution to avoid stockouts and backorders. However, it can also clog your available storage space, increase backorder costs, inventory costs, which could impact your overall budget.

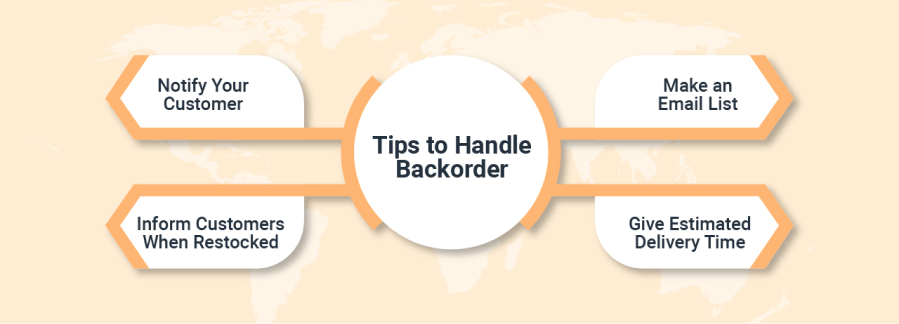

Effective Tips to Handle Backorders

Losing customers due to backorder can cause a big loss to your business. Customers can reach out to your competitor’s website to get the items they want. When customers cannot find what they want and are not satisfied with your services, you risk not only losing your customers but also it can impact your brand image.

Notify Your Customers

One of the best ways to handle backorders is notifying your customers that there is a stockout, but you will deliver the product to them by a determined date. Honest communication with the customers is always the key and your product page is the best place to do it.

Make an Email List

Get the email addresses of the customers who want to be notified when the particular product is back in stock. Use the scarcity principle to boost excitement among your customers. Creating a sense of urgency and excitement among potential customers is the best way to retain customers.

Inform Customers When Restocked

One of the best advantages of having an email list is that you can inform the customers as soon as the product is back in stock. Email all the interested shoppers and let them know that you have shipped the paid backordered orders. Keeping the customers engaged through emails is the best way to retain customers and encourage them to come for more to your website.

Give Estimated Delivery Time

If a product in demand is out of stock, make sure to post an estimated arrival time for it so that shoppers are not left in the dark. It helps you to keep the customers informed.

Say No to Backorders with Fulfillment Hub USA

At Fulfillment Hub USA, we use the best-in-quality inventory management tool to help you monitor the real-time status of stock levels, set safety stock and reorder points, get insights into your best-selling products, and more. With us, you can manage your inventory and order fulfillment perfectly while shipping your orders on time to boost customer satisfaction. To succinctly describe, we can help you to avoid the situation of backorder products. However, if you still get backorders, we can help you fulfill them adequately as soon as you replenish the inventory.

FAQs about Backorders

What does backorder mean?

An item on backorder means that it is currently out of stock, but will be the seller will deliver it to you by a certain date as soon as it is back in inventory.

How long does backorder take?

It depends on the retailer and product; however, backordered products usually take around 14 days.

What causes backorder?

A backorder is caused when a business gets orders for a product that is out of stock but will be back in inventory soon.

How to calculate backorder?

You can calculate the rate of backorder by dividing the number of unfulfilled orders by the total number of orders. Finally, multiply it by 100. It will help you to calculate the percentage rate.