Inventory is an asset to a company but when not managed properly, it can become a liability. Inventory management is a crucial part of warehousing and fulfillment centers. It ensures smooth, accurate, and timely order fulfillment. There are many inventory management methods, out of which Perpetual Inventory System is one of the highly adapted methods among businesses.

Perpetual inventory system manages the inventory ‘perpetually’ i.e., in real-time. It helps businesses stay up-to-date and provides better insights into inventory. But is it the best choice for your business? Let’s find out!

Manage inventory trouble-free with Fulfillment Hub USA!

Content Topic

- All About Perpetual Inventory System

- What is Perpetual Inventory System?

- Process of Perpetual Inventory System

- Difference between Perpetual Inventory System and Periodic Inventory System

- Businesses that use Perpetual Inventory System

- Different Types of Perpetual Inventory System

- Pros and Cons of Perpetual Inventory System

- To Sum Up

- Streamline Your Order-Fulfillment with Fulfillment Hub USA

- FAQs

All About Perpetual Inventory System

Inventory management of a business defines the quality of its order-fulfillment service. It has to be accurate and smooth to retain customers and stay ahead in the industry. Unfortunately, choosing a suitable method for your business isn’t easy. According to Compunnel Digital, 21.6% of companies are unsure which inventory management method suits their business.

Many businesses favor the perpetual inventory method because of its real-time updates and accuracy over other traditional methods. Continue reading this article to know more about it.

What is Perpetual Inventory System?

A perpetual inventory management system is an inventory accounting method that uses real-time tracking. It updates the data as soon as stock is added or shipped through every point of sale. Records get automatic updates for purchases and returns as well.

The president of Max Muller & Associates LLC and Author of “Essentials of Inventory Management,” Max Muller says,

“Perpetual inventory systems keep track in real-time. It uses software to follow the rules, keep the system up-to-date, and it works great. I recommend doing 3D-counting, where you count cross-sections often enough to account for the whole over time. You could consider this perpetual, but it would need to be software-driven and follow the rules or do a variation.”

To track inventory in real-time, a perpetual inventory system makes use of barcode scanning, radio frequency identification (RFID) scanners, and inventory management software. All the technologies and modern cloud-based software make perpetual inventory systems more practical. Additionally, it empowers financial and accounting departments and speeds up the process.

Process of Perpetual Inventory System

In a perpetual inventory system, inventory accounts are updated in real-time as soon as goods are bought and sold. Here is a quick run-through of how this system works:

1. Point-of-sale systems update the inventory levels

As soon as a sale happens, point-of-sale systems apply the debit to the inventory accounts across all sales channels.

2. Cost of goods sold is updated automatically

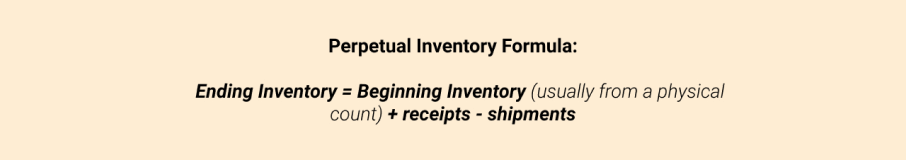

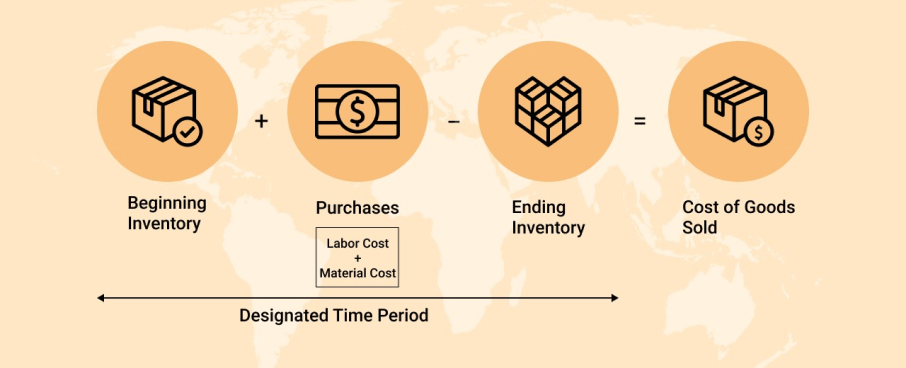

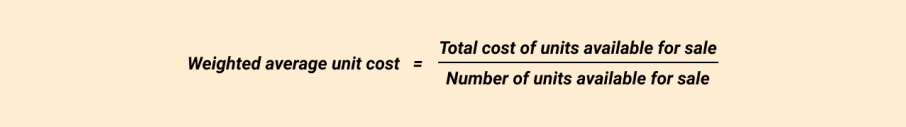

The cost of goods sold (COGS) gets calculated every time goods are sold or received. COGS is calculated as

3. Frequent monitoring of reorder points

A perpetual inventory system automatically updates the reorder point based on sales to keep an acceptable amount of inventory all the time.

4. Purchase orders are automatically generated

Whenever a reorder point is hit for a product, a purchase order is generated automatically and sent to the suppliers.

5. Received products are scanned and updated into the inventory

When new goods arrive at the warehouse, a warehouse management system (WMS) scans them and updates them automatically in the inventory accounts across designated sales channels.

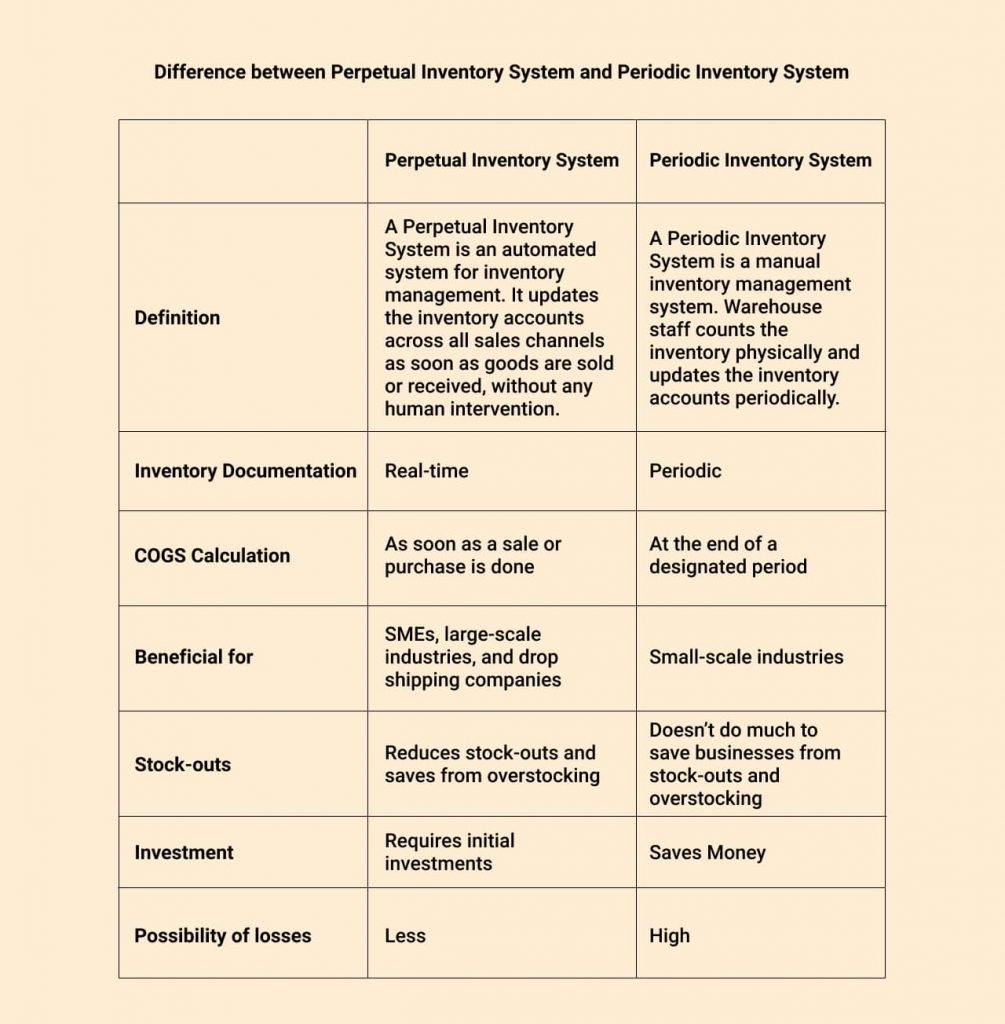

Difference between Perpetual Inventory System and Periodic Inventory System

Businesses that use Perpetual Inventory System

Automation is becoming a significant part of many businesses as it reduces human errors and improves accuracy within the system. However, when it comes to a perpetual inventory system, it is beneficial for few types of businesses.

The perpetual inventory system is best for businesses with multiple warehouses and large amounts of inventory. The system helps them maintain transparency and process the order quickly.

For example, you own clothing business and you receive an order for a Halloween costume in the month of March, which is rare. Now how will you find the costume across all your warehouses? Well, with the implementation of a perpetual inventory system, you can sit back and relax because with one click you can look for the costume across all your warehouses and fulfill the order with ease.

Small and medium-size businesses (SMBs) that are looking to grow rapidly can adapt to this method of inventory management. Additionally, it is a good solution for drop-shipping companies. Their products are always moving and to keep track of them, it is better to have real-time tracking in place.

Different Types of Perpetual Inventory System

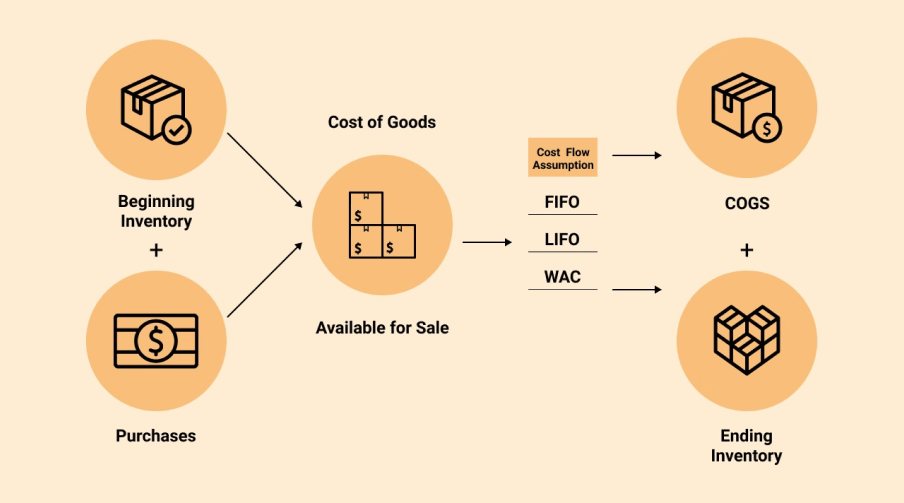

There are different ways to track inventory in a perpetual inventory system. It depends on the type of cost-flow assumption method you are using.

A cost-flow assumption is a method of inventory accounting that uses the original value of products from the beginning inventory of a period and purchases of new inventory during that period to calculate the value of ending inventory and COGS. There are three types of cost-flow assumptions: FIFO, LIFO, and WAC. Let’s dive into them!

FIFO Cost-Flow Assumption

FIFO is an abbreviation for first-in, first-out. It is a cost-flow assumption where you assume the first item added to the inventory is the first item sold. Hence, the inventory left at the end of the period is the recent purchases or products.

This method has maximum profits. Thus, it displays a higher bottom line and fewer COGS investments. Companies use this method to increase the share value.

LIFO Cost-Flow Assumption

LIFO is the last-in, first-out where you assume the last item added in the inventory is the first item sold. Thus, the leftover inventory is the first purchased stock. Businesses use this method to calculate the worth of their inventory.

It has higher COGS expenses and lowers net income/profits. Hence, companies use this method in tough times to decrease tax liabilities.

Weighted Average Cost-Flow Assumption

The weighted average cost (WAC) method uses the average cost of the entire inventory at the time of any purchase or sale.

The average cost is assigned to each unit when you make an inventory transaction. It also calculates ending inventory and COGS for a period. It yields a mid-range cost, hence, a mid-range profit. Moreover, businesses that don’t have inventory variation in their inventory prefer this method as it is simple and easy to apply.

Pros and Cons of Perpetual Inventory System

A perpetual inventory system makes the inventory management process smooth. However, to decide if this method suits your business or not, here are some pros and cons:

Pros

- A good perpetual inventory system provides a better inventory control.

- It helps in preventing stock-outs and overstocking.

- With up-to-date inventory count, you will save a lot on inventory and storage costs.

- Perpetual inventory system keeps the database updated and reduces inventory shrinkage.

- Continuous monitoring of inventory provides better understanding of consumer preferences and helps in accurate forecasting.

- It complements other inventory management methods like FIFO, LIFO, and WAC.

- Centralization of inventory becomes easy with perpetual inventory system.

- It allows businesses to adapt omnichannel approach.

Cons

- Software can’t always be accurate, and hence, there’s a high chance for discrepancies.

- It is time-consuming to rectify an error.

- The system demands high initial investments, which makes it expensive for small businesses.

To Sum Up

The goal of using any inventory accounting and management method is to streamline the operations. If this is achievable with a perpetual inventory system for your business, then adapt the technique without any doubt. On the other hand, if it is challenging to optimize operations with the perpetual system, there’s always an option to use either the periodic method or an even better hybrid approach of the perpetual and periodic inventory system.

Streamline Your Order-Fulfillment with Fulfillment Hub USA

We, at Fulfillment Hub USA, have automated our order-fulfillment services to ensure accuracy and on-time delivery. Our team equips you with warehouse management software that provides you with real-time updates of your inventory, tracks your packages, and helps you in planning and forecasting for your business with detailed insights.

Get ahead of your competitors with our top-notch services. Connect with our experts today to streamline your operations and manage your inventory effectively.

FAQs

What is a perpetual inventory system?

A perpetual inventory system is an inventory management method that tracks the inventory in real-time. Databases gets updated as soon as goods are sold or received.

How does a perpetual inventory system work?

With the help of inventory management software, a perpetual inventory system tracks everything and updates the database across designated sales channel.

Why do companies use perpetual inventory system?

A perpetual inventory system allows businesses to save inventory and storage costs and helps them manage inventory accurately with automation.

What is the advantage of perpetual inventory system?

It provides better inventory management and is more accurate than the periodic inventory system.

Which one is better: perpetual inventory system or periodic inventory system?

For businesses with multiple warehouses, perpetual inventory system is the best choice. However, periodic inventory system is better for small businesses. There’s always an option to use a hybrid approach to streamline various business operations.